What To Look For in A Robotic System Integrator

What to Look for in a Robotic System Integrator

Whether you're a first-time buyer of industrial robots or have worked with automation systems before, choosing the right robotic system integrator is crucial for your next project. But how do you identify the best fit? Here's what to consider when selecting a robotic system integrator.

Why You Need a Robotic System Integrator

A robotic system integrator plays a vital role in helping you design, implement, and maintain an automated solution that aligns with your business goals. They assess your facility’s needs, develop a tailored automation strategy, and ensure your system runs smoothly from start to finish. By partnering with a qualified integrator, you can reduce downtime, improve productivity, and achieve long-term cost savings.

These professionals are equipped to handle a wide range of applications, such as assembly lines, material handling, palletizing, painting, welding, and more. Their expertise ensures that your automation project is both efficient and scalable.

Key Factors to Consider When Hiring a Robotic System Integrator

1. Experience and Reputation Matter Not all integrators are created equal. Some may have years of experience working with similar industries, while others may lack the necessary background. Choose an integrator with a proven track record and positive reviews from clients in your sector. Ask for case studies or references to better understand their past successes.

2. Look for Technical Expertise and Problem-Solving Skills A strong integrator should be able to analyze your current processes and identify areas where automation can bring real value. They should also be capable of addressing unique challenges specific to your application. This requires not only technical knowledge but also creativity and adaptability.

3. A Good Integrator Will Help You Plan Once they understand your needs, a reliable integrator will create a detailed automation plan. This plan should take into account your budget, technical requirements, compliance standards, and safety protocols. It should also outline strategies for maximizing efficiency, minimizing disruptions, and ensuring continuous operation.

4. Execution Is Just as Important as Planning Having a solid plan is one thing, but executing it effectively is another. An experienced integrator knows how to test, install, and fine-tune your system to ensure it performs as expected. They should also provide training and support to help your team get up to speed quickly.

5. Ongoing Support Is Essential Automation isn’t a one-time project—it’s an ongoing investment. That’s why it’s important to choose an integrator who offers long-term support. Whether you need maintenance, troubleshooting, or updates, having a partner who is available and responsive can make all the difference. If your business operates in multiple locations, look for an integrator with a broad service network.

At Genesis Systems, we offer 24/7 support to ensure your robotic systems run smoothly at all times. With our dedicated team, you can rest easy knowing that help is always just a call away.

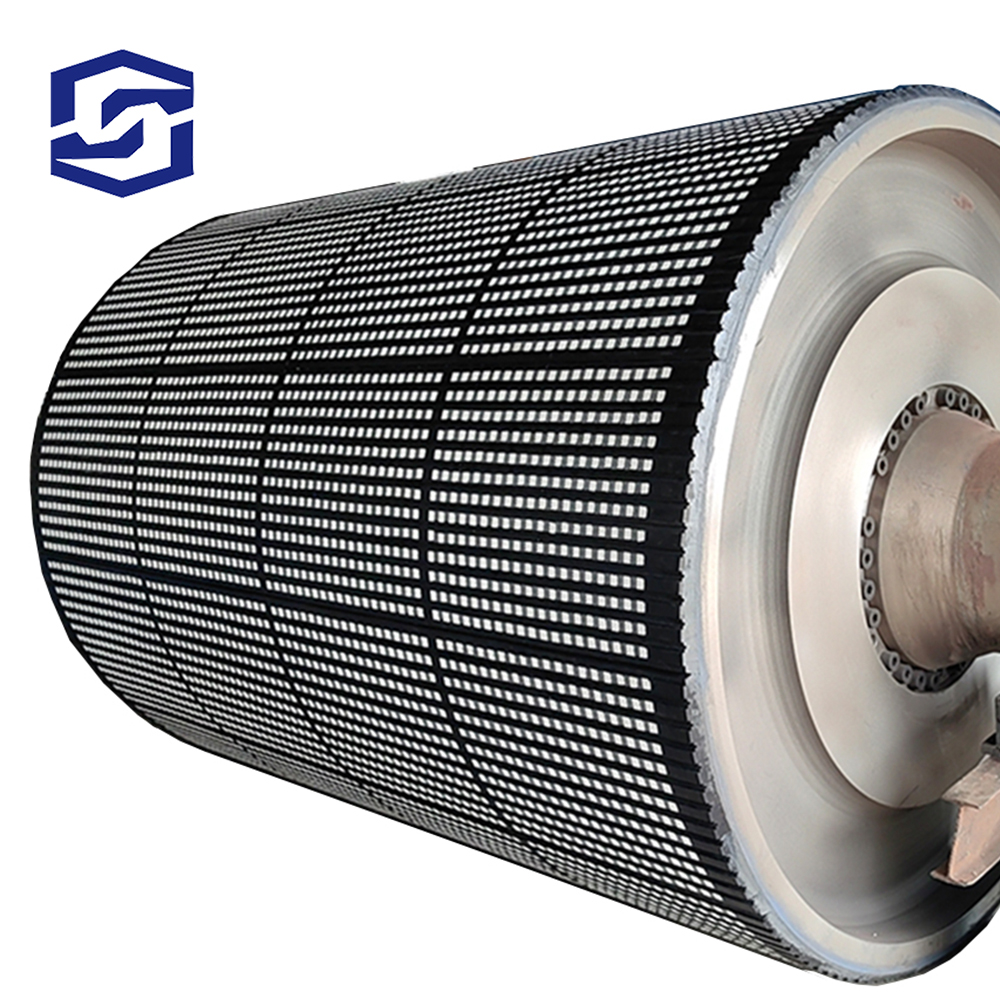

Posted in UncategorizedRoller Covered Ceramic Rubber Sheet

ceramic rubber plate,belt conveyor roller covering ceramic rubber sheet,Roller covered ceramic rubber sheet,Wear resistant ceramic rubber sheet,ceramic rubber lagging

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com