What Do Industrial Ovens Do?

What Do Industrial Ovens Do?

Updated: December 22, 2023Industrial ovens are essential tools in a wide range of manufacturing and production environments. These high-performance heating systems are used to complete various thermal treatments, from curing coatings to sterilizing medical equipment. Whether you're working on large-scale projects or smaller batches, an industrial oven can be tailored to meet your specific needs.

There are several types of industrial ovens available, each designed for different applications. Understanding the differences between them can help you choose the right one for your business. Two of the most common types are batch ovens and continuous ovens, each offering unique benefits depending on your production volume and requirements.

Industrial ovens are not just about heating—they play a critical role in ensuring product quality, consistency, and safety across multiple industries. From pharmaceuticals to automotive and food processing, these ovens are indispensable in modern manufacturing processes.

What Is an Industrial Oven?

At its core, an industrial oven is a heated chamber designed to apply controlled heat to materials, components, or finished products. These ovens come in a variety of sizes and configurations, with walk-in models being particularly popular due to their flexibility and capacity. Depending on your application, you may choose between two primary types:

- Batch Ovens: Also known as walk-in ovens, batch ovens are ideal for processing groups of items at once. Products are placed on carts or trays and moved into the oven for uniform heating. This type is perfect for smaller runs or when different batches require separate treatment.

- Continuous Ovens: These are best suited for mass production environments where a steady flow of products needs to be processed. They often feature multiple zones—some for heating and others for cooling—to ensure efficiency and speed in the production line.

Industrial Oven Uses

Industrial ovens are incredibly versatile, serving a wide array of purposes across many industries. Whether it's baking coatings, drying materials, or sterilizing equipment, these ovens are a vital part of the manufacturing process. Some of the most common applications include:

- Baking Pill Coatings: In the pharmaceutical industry, ovens are used to bake protective coatings onto pills and remove excess chemicals using thermal oxidizers.

- Drying Equipment and Materials: Industrial ovens help dry laboratory instruments and cure tablets, ensuring they meet quality and safety standards.

- Sterilizing Medical Instruments: In healthcare settings, ovens are used to sterilize surgical tools and decontaminate other medical supplies like syringes and scalpels.

- Heat-Treating Materials: Many materials undergo heat treatment processes such as aging, tempering, and annealing to improve their strength, durability, or flexibility.

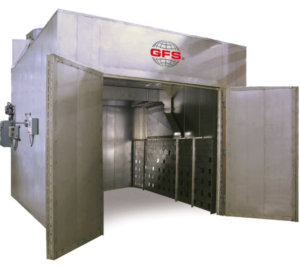

Select Walk-In Ovens From Finishing Systems

If you're looking for reliable and high-quality walk-in ovens to support your manufacturing operations, Finishing Systems is the trusted partner you need. With nearly 50 years of experience, we specialize in designing and manufacturing industrial ovens that deliver exceptional performance and durability.

Our ovens are built to handle a wide range of tasks, whether you're dealing with small batches or large-scale production. We offer cost-effective solutions that are both efficient and easy to maintain. From installation to user training, our team ensures that your new oven is up and running smoothly from day one.

Upgrading your facility with a new industrial oven can significantly improve your productivity and product quality. If you're ready to take the next step, contact us today to learn more about how we can help you find the perfect oven for your needs.

Contact Us Today

Compared to traditional bicycles, folding bicycles can be more convenient to use.

The small size of the foldable Bike allows you to take it on buses, subways and other means of transport or in lifts, making it the best choice for convenient urban commuting. You can easily put it in the trunk of your car and take it to your destination to ride your bike, and it's affordable, compared to mountain bike road bikes which are more cost-effective in price. The Foldable Bike Parts usually cheaper than the mountain bike parts. Such as the Bicycle Hub, the frame, etc.

However, the drawbacks are also obvious; the folding frame are not as strong as the one-piece frame of a mountain bike, and climbing hills is more strenuous than with a mountain bike, btw, the front Folding Bike Hub is too small for force. It is slower and less comfortable than a mountain bike on long rides.

If you ride in the city, or go for a short ride once in a while, it is fine to buy a folding bike. If you climb a lot, like to go off-road, or ride long distances, the mountain bike or the road bike is more recommended.

Folding Bicycle Hubs,Folding Bike Hub,Folding Hub,,Foldable Bike Parts

Suzhou Jingqiyao Intelligent Technology Co., Ltd. , https://www.polsobike.com