Mining Drones: Elios 2 Creates Photogrammetric Models

Mining Drones: Elios 2 Enables Photogrammetric Modeling

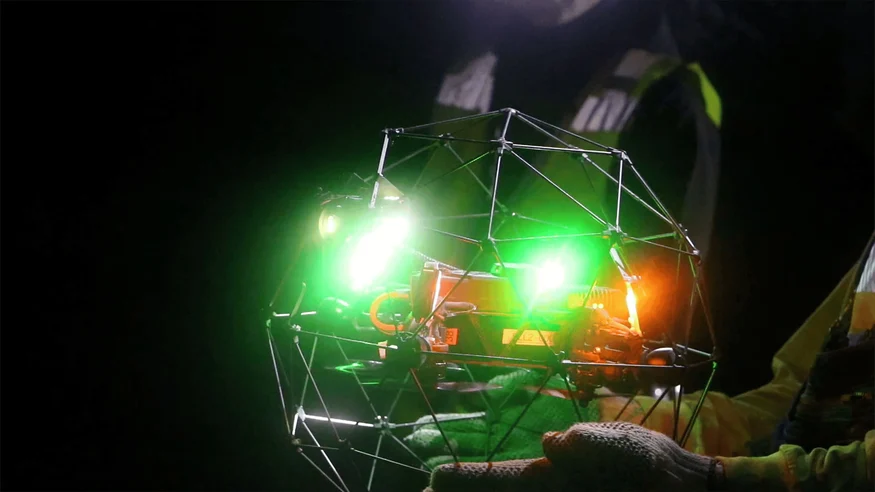

Drones have become a staple in the mining industry for mapping open-pit mines, but exploring underground environments remains a major challenge. The Elios 2 is changing the game by offering a cutting-edge solution that brings photogrammetric capabilities to dark, GPS-denied areas deep beneath the surface.

Key Benefits at a Glance

|

Safety

By capturing visual data from dangerous zones, the Elios 2 enables safety assessments that were once impossible, reducing risks for workers in hazardous underground conditions. |

High-Quality Data

The drone delivers 4K video and high-resolution images, providing critical insights for operations, engineering, and safety teams, helping to optimize stope development. |

Easy to Use

With its stabilized flight and durable caged design, the Elios 2 allows for thorough inspections without the risk of crashes, even in tight spaces. |

Introduction

For three days, Flyability’s Elios 2 was tested at Barrick Gold Corporation’s Golden Sunlight Mine in Whitehall, Montana. This compact, rugged drone was designed specifically for confined space inspections and proved to be a game-changer in underground mining.

Matt Mackinnon, founder of Unmanned Aerial Services, Inc., played a key role in guiding the development of the Elios 2. His goal was to showcase how the drone could enhance safety and provide better access to visual data in challenging underground environments.

The results were impressive. “The Elios 2 checks nearly every box for what we need in underground inspections,†Matt said. “From stability and image quality to its ability to reach tight spaces, it exceeded our expectations.â€

Using data collected during flights, the team created a detailed 3D photogrammetric model of a stope—a large void left after ore extraction. This model provided critical insights into the stope's condition, helping identify loose material, potential hazards, and remaining ore deposits.

Customer Needs

After blasting, large rocks can become unstable inside a stope, posing serious risks to both miners and equipment. Traditional inspection methods are limited—either using boreholes or poles, which offer only partial visibility.

This lack of visibility leads to potential damage to expensive machinery like muckers, which can cost over a million dollars each. It also increases the risk of accidents and can result in lost ore due to undetected deposits.

Barrick needed a reliable way to gather visual data from inside the stope to ensure safety, protect equipment, and avoid costly losses. The Elios 2 offered the perfect solution.

[Related read: What is a LiDAR drone?]

Solution

Ryan Turner, a geotechnical engineer at Barrick, worked alongside Matt Mackinnon and the Flyability team to conduct multiple inspections at different stopes. He was impressed by the ease of use and reliability of the Elios 2.

“It’s safe to interact with, and the cage protects it from collisions,†Ryan noted. “You can take it off the shelf and fly it in one of the harshest environments we work in.â€

Results

The Elios 2 successfully navigated large spaces and tight shafts, capturing high-quality images and data that were more accurate than previous methods. Its powerful lighting system helped illuminate even the darkest corners, and the protective cage prevented damage during collisions.

One of the most valuable outcomes was the creation of a 3D photogrammetric model of a stope using Pix4D Mapper. This model provided a detailed snapshot of the site’s condition, revealing the full volume of the excavation and helping engineers assess structural stability.

“The imagery looked really good,†said Ryan. “We could see where structures were releasing material and get precise data for risk assessments.â€

Even employees with no prior drone experience found the Elios 2 easy to fly. During testing, a geologist and a mucker operator were able to control the drone effectively, proving its user-friendly design.

“This is a drone you can hand to someone who’s never used it and they’ll be successful,†Ryan added. “It’s rare to find a drone that’s both easy to fly and capable of operating in harsh underground conditions.â€

Photogrammetric Mapping – In Testing and Development

In addition to live video feeds, the Elios 2 collected enough data from four flights to create a 3D photogrammetric model of part of the mine’s stope. These models help engineers track changes over time and make informed decisions about future operations.

Geologists can use these maps to compare before-and-after conditions, identify shifts in rock formations, and assess the risk of collapses. By clicking on specific points, inspectors can view original images and analyze geological features in detail.

These models are not just for analysis—they also support long-term planning, helping engineers design safer and more efficient mining operations.

Conclusion

The Elios 2 has opened new possibilities for Barrick Gold and UAS Inc., allowing them to access previously unreachable areas and collect vital visual data for decision-making. With 3D photogrammetric models, they can now improve ore control, reduce risks, and protect both personnel and equipment.

This technology has the potential to save millions in production losses, equipment damage, and ore dilution. As part of a broader series on photogrammetry, this article highlights how drones like the Elios 2 are transforming the mining industry—one model at a time.

This article is part of a series on photogrammetry:

- Why use photogrammetry for indoor 3D modeling?

- Mining Drones: Elios 2 Creates Photogrammetric Models

- How to Collect Data for Photogrammetry with Elios 2

- Processing Data with Photogrammetry Software

- Elios 2 Tested for Stockpile Volumetry, Produces Accurate 3D Maps

Brake Pad Coating Lines,Disc Spray Line,Disc Spraying Line,Disc Sprayer

Pujiang Longhui Machinery Co., LTD. , https://www.longhuimachinery.com